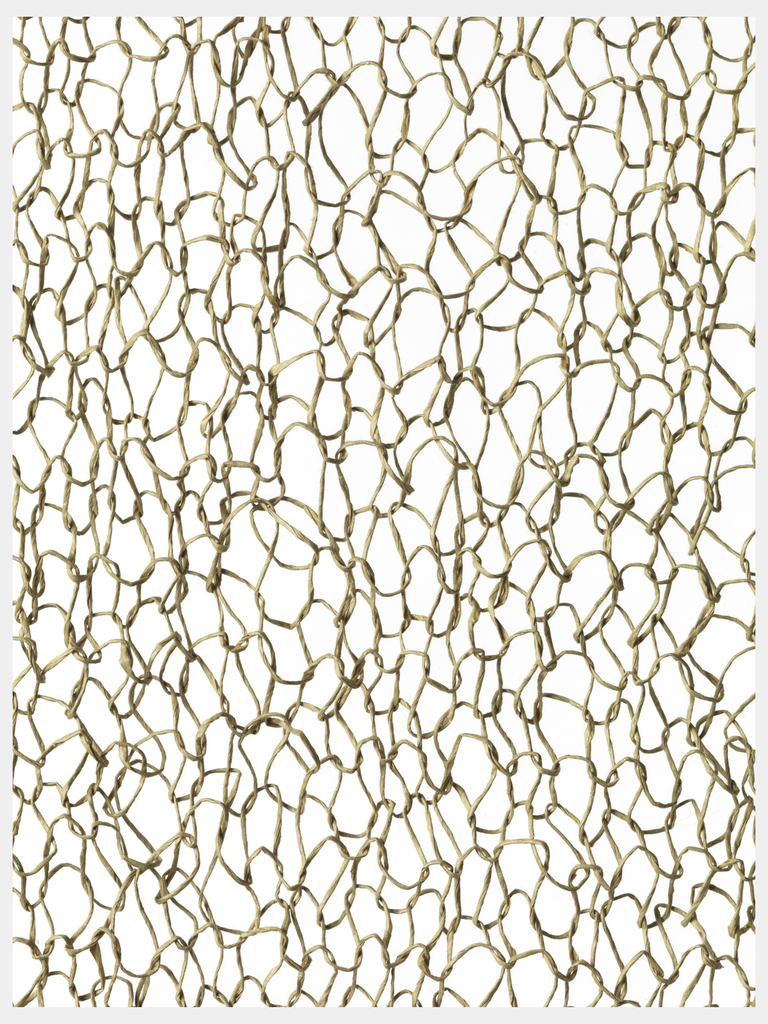

Textile, Veil curtain, 2007–08; Designed by Rita Puotila (Finnish, 1935); biodegradable spun kraft paper yarn; 257.8 x 129.5 cm (8 ft. 5 1/2 in. x 51 in.); Gift of Woodnotes; 2011-43-1

B for Biodegradable

While natural and synthetic fibers are nearly 100% recyclable as long as they are not blended, not all textiles are 100% biodegradable. A cradle-to-cradle material must be both recyclable and degradable to be fully sustainable. Textiles made from natural fibers such as hemp, cotton, jute, silk, and wool can return to the ecosystem with the help of animals and microorganisms in the soil. However, the majority of fabrics are composed of artificial fibers, often petroleum-derived, such as polyester, nylon and spandex. Polyester is fully recyclable but not biodegradable and will take several decades to break apart. Many textiles are also made of fiber blends mixing natural and synthetic yarn, which jeopardizes full disintegration.

Any textile-based solid waste—whether synthetic or natural—that is buried in landfills will release greenhouse gases as it decomposes. It produces methane, a particularly destructive substance responsible for global warming.[1] In landfills, industrially-made textiles, including natural-fiber fabrics, contain chemicals that will eventually leech into the soil and contaminate groundwater. Chemicals and heavy metals such as mercury, chromium, zinc, and formaldehyde are used in dyestuffs, processing, printing, and finishes applied to fabrics; and a large part of these components remain in the fiber.[2] In western countries, especially in the EU, the use of heavy metals and harmful chemicals has been severely restricted in the textile industry. But there is still a lot of progress and regulation to expect from developing countries. Landfills lack oxygen, water, and the right kind of microorganisms, which makes them an environment unsuitable for biodegradability.

To prevent sending textiles and garments to trash, a handful of companies have started to develop innovative compostable textiles that will break down into enzymes and humus under industrial compost conditions. A textile can be labeled compostable if it meets certain industrial standards—ASTM D6400 and ASTM D6868 that are issued by the Biodegradable Products Institute, in the case of polymer products. To receive certification, a minimum of 60% of the fabric must disintegrate into carbon dioxide and biomass within six months in a certified composting facility. In addition, research on bioplastics made of biodegradable synthetic polymers, or derived from natural sources such as corn starch and sugarcane, has become an emerging field, especially for medical textiles. Investing in these new scientific developments and technologies will help to turn biodegradable and compostable textiles into valid solutions to tackle the major environmental issue of textile waste.

[1] Planet Aid, What We Do for the Environment: Recycling Textiles, 2016, accessed July 2016. http://www.planetaid.org/what-we-do/for-the-environment/recycling-textiles

[2] Greenpeace, Eleven Hazardous Chemicals Which Should Be Eliminated, accessed July 2016. http://www.greenpeace.org/international/en/campaigns/detox/fashion/about/eleven-flagship-hazardous-chemicals/

About the Author

Magali An Berthon is a textile researcher and designer, focusing in particular on world textile crafts and sustainable fashion. After an MFA in textile design in Paris, she studied textile history at the Fashion Institute of Technology NY on a Fulbright fellowship in 2014. Since June 2015, she is a curatorial fellow at the Textile Department at Cooper Hewitt, Smithsonian Design Museum.

Scraps Stories

This post is part of the blog series Scraps Stories dedicated to exploring sustainable textiles and fashion, in relation to the exhibition Scraps: Fashion, Textiles, and Creative Reuse.

One thought on “Green Glossary: B for Biodegradable”

Catherine Mick on January 11, 2017 at 1:12 pm

good news,this new news to me. I have been recycling fine fabrics, silk, wool, cotton etc, by making a yarn , by ripping or cutting when my inCquisitive fingers have ‘found a good one’. These can be used in weaving, machine or hand knitting, crocheting,even a bit of embroidering and plying on spinning wheels.

This avenue of investigating started in the mid-80’s.

Have spread the word since then in Australia, New Zealand, half of USA, all of Canada from 1980 to present time. Very rewarding to see others are making use of fabrics with much ‘life’ left in them.