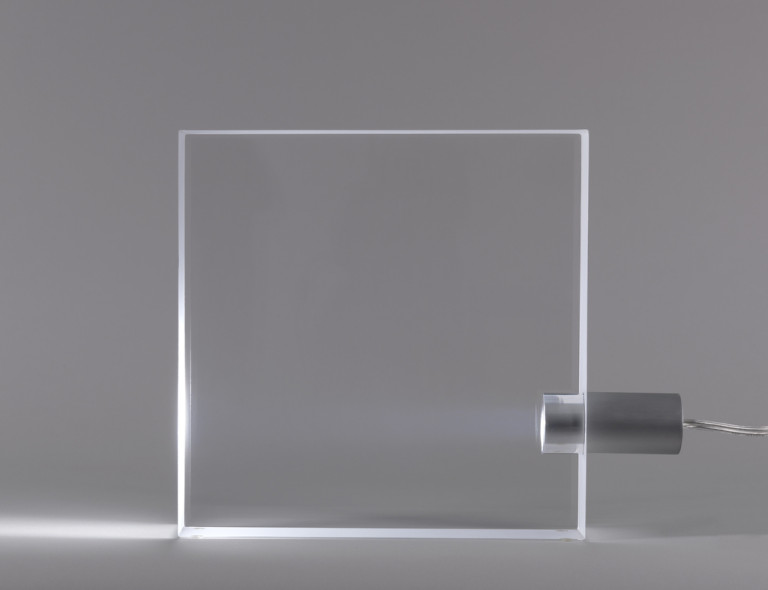

Tokujin Yoshioka’s ToFU lamp is magical. The spare form—a square cut delicately from clear methacrylate resin—conducts light only around its edges, stemming from a single halogen bulb. It is as though light itself is harnessed in the design, caught within and released by the material in a minimal, sensual gesture.

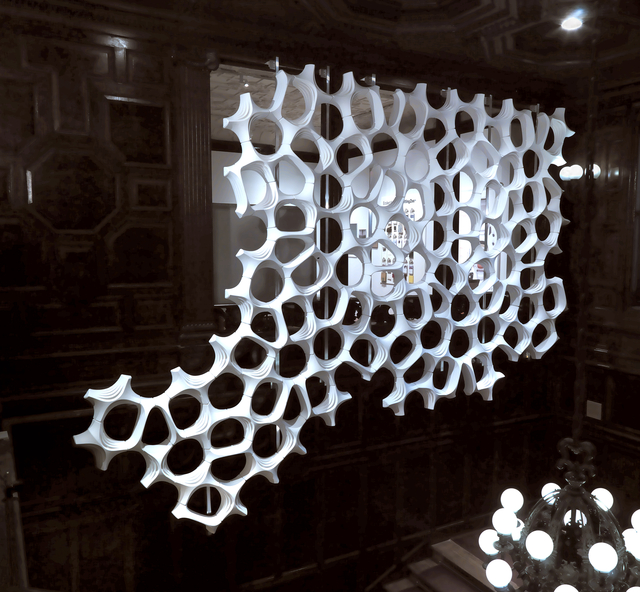

The MyLight.MGX, a hanging lamp by designer Lars Spuybroek for Belgian-based manufacturer Materialise NV, illustrates the possibilities of computerized production methods. Made in 2007, it was digitally printed (also known as 3D printing) using the process of Selective Laser Sintering (SLS). With SLS, a computer controls an infrared laser that solidifies miniscule layers of powdered material—in this case, polyamide, or nylon. The object is then additively built, layer upon layer. There are no molds, there is no assemblage of multiple parts. The object is printed in its entirety.

The ProSolve 370e system consists of modular architectural tiles coated with titanium dioxide that, when activated by daylight, neutralizes nitrogen oxides—harmful for their effect on the respiratory system, acid rain, and ozone depletion—in the surrounding environment. While the antimicrobial and air-purifying effects of titanium dioxide have been known for years, it is the form and application of ProSolve that is particularly innovative.